19 June 2023

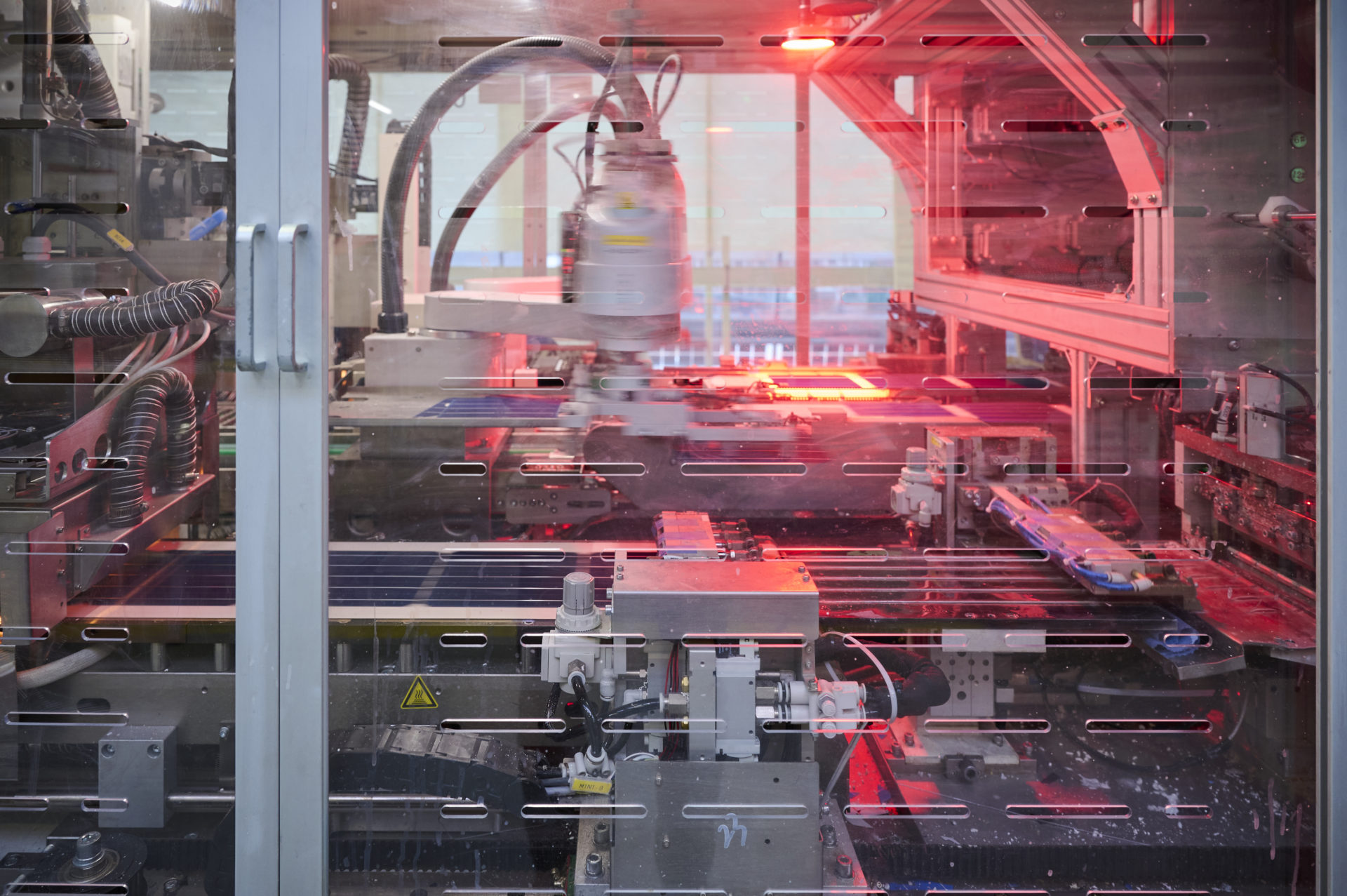

High tech in the warehouse: innovative building-integrated photovoltaic systems are produced at the site in Gwatt. Source: Energiejournal – Energieschweiz.

By Roland Grüter (text) and Gerry Nitsch (photo) – Energy Magazine for Homeowners 2023-05-23

More than 70 per cent of the photovoltaic modules installed in Switzerland come from Asia. However, a few highly specialised Swiss companies are able to hold their own against the Asian dominance. One of these is 3S Swiss Solar Solutions based in Gwatt (BE), whose building-integrated solutions are in great demand.

Right next to the door of the head of 3S Swiss Solar Solutions’ office, a leading manufacturer of photovoltaic systems, is written in large letters “Creating something new with passion”. The company’s modules are installed on about 20 000 Swiss roofs. The Gwatt site employs 130 people, four times as many as only five years ago. At first glance, it may look like a bank or an insurance company: offices behind imposing sheets of glass, meeting rooms in perfect order.

But appearances can be deceptive: as soon as you open the door on the other side of the building, you enter a totally different environment: a 2,000-square-metre hall, where high-tech and people work in perfect harmony. Robotic arms lift sheets of glass, flashes of light strike the modules. Workers solder copper wires and remove film residues. Every day, more than 25 tonnes of material are handled. It takes around 20 processing steps before we see the brand new photovoltaic modules, including the speciality of the house, the MegaSlate panels. The Federal Office of Energy recently awarded the company the well-known ‘Watt d’ Or’ prize. A veritable endorsement.

Blended with architecture

“We produce building claddings capable of generating the energy of the future” reads the company’s website. The highlight: the solar modules are not mounted on the roof like any other, but integrated directly into the building envelope. They replace conventional roof tiles, cover roofs, car parks, facades or balcony railings right up to the furthest corner, blending in with the architecture. They thus differ from the usual laid systems offered by many competitors in the Far East. And with success: last year the company doubled its sales and is again counting on solid growth for the current year.

Part of the team of 16 is taking a break in the warehouse.

The management offers a brunch as a reward for the production record achieved the previous week. The workers raise their hands in greeting as the boss hurries past them. Marcus Bäckmann is in charge of the company management. Today, however, he accompanies visitors through his realm. He stepped in to replace the company’s founder and main shareholder, Patrick Hofer-Noser, who had an accident while on holiday. Marcus Bäckmann’s passion for the company and its staff can be felt in every word he says. Although the company has grown considerably, the atmosphere seems familiar.

The beginnings in mechanical construction

The company’s history is eventful. Originally founded in 2001 in Lyss (BE) by Patrick Hofer-Noser, with the aim of achieving energy self-sufficient and CO²-neutral buildings, it first dedicated itself to the automation and production processes of photovoltaic modules. 3S thus became a machine building company. A merger with Meyer Burger, another machine manufacturer, followed in 2010. Together they experienced their golden years, developing photovoltaic modules that today are considered conventional. As Asian competition entered the scene, the group decided to diversify, selling off or closing down parts of the company. In August 2018, Patrick Hofer-Noser bought back the building-integrated photovoltaics business, continuing the path he had started 17 years earlier.

This was not a simple matter. Although Swiss research has always contributed to the advancement of photovoltaic technologies, the local industry has not been able to really exploit this advantage in terms of know-how. When production was automated about ten years ago, many companies did not seize the opportunity and production took place elsewhere. For the few companies that wanted to challenge foreign competition, only niche markets remained. So most turned to building-integrated photovoltaic systems.

European manufacturers are few, but of very good quality. Besides 3S Swiss Solar Solutions, there are Meyer Burger, Sunage, Axsun, Aleo, Sonnenkraft and Enel. “The younger generation will hardly know that Switzerland was once the leading nation in Europe

in the production of photovoltaic energy,” writes the Swiss Federal Office of Energy in its argumentation for the Watt d’ Or award. “One of the pioneers of the golden age of solar energy in Switzerland is 3S Swiss Solar Solutions.”

Uneven battle

All that remains of the golden days is a memory. More than 70 per cent of the PV modules installed in Switzerland now come from abroad, mainly from China. “The Chinese government recognized the potential of photovoltaics early on and promoted it, not least to secure the country’s energy supply,” says Marcus Bäckmann. “The domestic market is huge and only a small part of Chinese production is exported.” In the US, the sector also enjoys state support. David Stickelberger, Director of the Swiss Solar Professional Association Swissolar, says: “Today, European investors’ money and a lot of know-how goes to the US. It’s an uneven fight, in which Swiss and European competitors can’t hold a candle to their rivals. We finance research, but not industry.”

This has resulted in a considerable dependency, from which Europe wants to break free in the coming years. In fact, the EU has set itself the goal of bringing back 40% of production. A corresponding law is being prepared. Another intends to make the origin of photovoltaic modules more transparent. Where do the components come from? Are human rights respected in the processing chain? The policy goals are ambitious.

‘But it pays to take action,’ Marcus Bäckmann is convinced. “Dependence on Asia is very risky and urgently requires a change of perspective if we are not to jeopardise our energy policy goals.”

Solar electricity already makes an important contribution to the country’s energy supply. However, in order to move away from fossil fuels and nuclear power, Switzerland needs at least ten times more solar power than it has today. To achieve this, it must have reliable framework conditions and also the certainty that the necessary technology is accessible. ‘Trade routes are fragile,’ says expert Marcus Bäckmann. “The war in Ukraine has made this abundantly clear to us.”

For many property owners, the question of the origin of solar modules is also becoming increasingly important. It is a question of how long a solar module has to produce environmentally friendly electricity to compensate for the CO² emissions generated by production and transport. “In this, systems produced in Europe or Switzerland have a clear advantage,” says David Stickelberger.

The factory visit is over; it is now time to take a look at the future. The company has big plans. At the end of the year it will open a second location in Worb (BE) with a highly automated production line, which will triple its capacity. Also on the way is the new TeraSlate product, which is more efficient than its predecessor.

Where does 3S Swiss Solar Solutions see itself in ten years? “In our segment, we want to become a major player on a European level,” says Marcus Bäckmann. He points to a yellowed piece of paper, on which it reads: ‘Creating innovations with passion’. The slogan comes from the meeting in which, after the take-over, the management reflected on its philosophy. It is a motto that is destined to last.