December 11th, 2023

Selection of pictures from different manufacturers and R&D projects. Top: Smart-Flex, PV Construct – bottom: Meyer Burger, HSLU). Source: SUPSI.

Introduction

In recent years, the photovoltaic (PV) market has experienced significant growth in crystalline silicon (c-Si) modules. Initially, these modules were predicted to decline in popularity as second-generation thin film PV technologies seemed more promising and affordable. However, the combination of decreasing c-Si prices and increasing efficiency reversed this trend. Innovative c-Si architectures, such as back-contact solar cells and hetero-junction c-Si as well as Passivated Emitter Rear Contact (PERC) technologies, emerged, pushing commercial module efficiencies above 20%, making it more attractive for the BIPV market.

Currently, crystalline silicon comprises about 90% of new processed cells and modules. To stay competitive, c-Si suppliers need to diversify their products and reduce costs further. The main drivers for this diversification are efficiency, energy yield, and aesthetics, particularly for building-integrated PV. New glass structures, encapsulants, and anti-soiling coatings are being proposed for this purpose.

Bifacial modules, which absorb light from both sides, have recently entered the market, increasing the efficiency of modules. However, accurately measuring the electrical performance of bifacial modules is challenging due to reflections from the backside. Standard measurement procedures are lacking, as bifacial modules fall outside the scope of existing standards like the IEC 60904 series. The implementation of a standard measurement procedure for bifacial architecture into the IEC 61853 energy rating standard is under discussion.

Scope of the ENHANCE project

The ENHANCE project, conducted by SUPSI PVLab, the only Swiss laboratory accredited to ISO 17025 for testing photovoltaic modules, aimed to assess the test procedures for bifacial modules and to assess the performance of mono and bifacial coloured PV modules. The project dealt with indoor and outdoor testing, with a detailed characterization of the modules in the laboratory and the measurement of the energy production of coloured versus reference modules in the field. The indoor tests included power rating assessment following the new IEC 60904-1-2 standard for bi-facial modules and the determination of the spectral response of coloured modules. The outdoor measurements consisted in the measurement of the energy yield and the calculation of key performance indicators (KPIs) like the energy yield in kWh and the specific energy yield in kWh/kWp.

Here listed are the main project tasks:

- Procurement of modules for a new outdoor measurement campaign focused on emerging PV technologies, with an emphasis on aesthetics and bifaciality.

- Characterization and demonstration of efficiency losses or gains associated with new module architectures or coatings.

- Test different methodologies for characterizing bifacial modules.

- Contribute to the development of new international standard test methods in collaboration with other stakeholders.

SUPSI-ISAAC outdoor test stand. Reference modules were placed next to the corresponding-coloured modules. Source: SUPSI.

Modules A1/A2 and B1/B2 are made with the ceramic digital printing technology developed by the Lucerne University of Applied Sciences and are designed to ensure that the non-uniform shading by the printing does not lead to mismatch losses or hot-spots. The two modules B1/B2 differs in the use of bifacial hetero-junction cells.

Additionally, two terracotta modules with different colour treatments have been tested. Module C is a module made with a uniform ceramic digital printing technology and with a thicker prism-shaped textured glass for facade applications, while module D is based on a mineral coating technique on glass deposited at high temperatures.

The selective filter of the white module E was developed at the Centre Suisse d’Electronique et de Microtechnique – CSEM and it is capable to reflect and diffuse the visible spectrum providing a white appearance, while the infrared part is transmitted and converted into electricity. Thereby, there is an substantial efficiency reduction in comparison to a traditional module, but with a higher esthetical value and invisible cells.

Module F has a full-surface printing with UV-resistant and translucent special inks.

Ideally, an identical module without colour treatment (same cells, interconnection, and manufacturing) was measured for direct comparison. If not available, a commercial module with the same cell technology and similar cell efficiency had to be used instead.

Comparison of the loss in energy yield between different photovoltaic modules. Source: SUPSI.

Loss in energy yield in aesthetic modules

The loss in energy yield caused by the different colour treatments or other aesthetics changes, depend on many factors. To better understand the performance under real operating conditions, the coloured modules were monitored for an entire year (starting from 1 May 2018) together with their reference modules and the difference in kWh respect to these was reported. Depending on the colour of the coating and its density, a yield loss of 16 up to 45 % was detected.

As expected, the losses in short circuit current and respectively in power and energy production are the highest for the modules in which the cells are completely hidden behind the coating (extent of cell camouflage). Among the modules that were sampled, those with the highest loss are therefore the white module and terracotta-facade system with deep structured glass.

The lowest difference is observed in the terracotta-module with a more transparent mineral coating, where a compromise has been made between aesthetics, entailing higher visibility of cells and cell contacts, and lower energy yield losses.

The bifacial modules are showing the lowest loss within the modules with partially hidden cells, because of the additional light captured from the back.

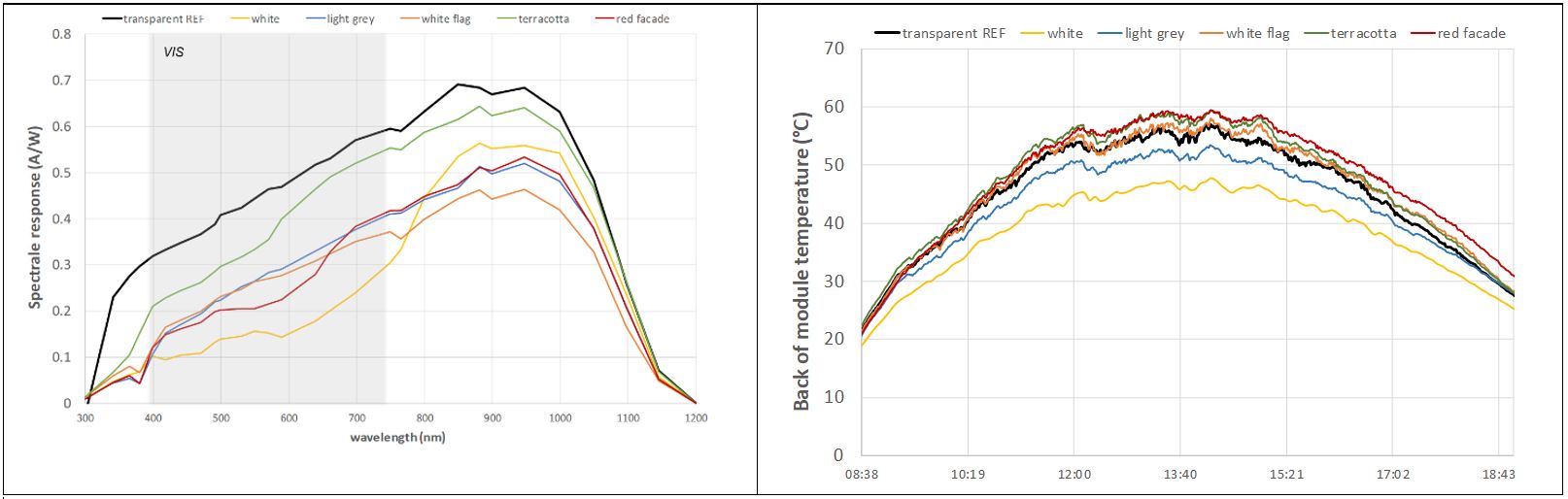

To better understand the impact that coloured coatings have on the energy yield, the spectral response and module temperature were analysed.

Spectral response curves for the different modules as well as an example of module temperature measured over a clear sky day. Source: SUPSI.

Conclusions

Aesthetic modules using ceramic digital printing, selective filters, and textured glass were studied to explore the effect of different colour treatments and appearances. The tested modules ranged from red/terracotta to white/grey, including both plain and multi-colour designs. One module featured bifacial cells.

- Plain-coloured modules showed a decrease in performance, ranging from 16% to 45.5%, depending on the colour and coating thickness. The white module with completely hidden cells had the highest performance loss.

- Multi-colour modules, potentially affected by mismatch losses caused by the non-uniform transparency of the coatings, showed relative performance difference of only 5%, which is the proof that mismatch losses can be minimized through a careful design of the printed layer.

- As expected, the white module with the spectral selective filter reflecting the visible spectrum showed a significant loss, which is however partially compensated by a up to 10ºC lower module temperature respect to a traditional module.

- The use of bifacial cells is an effective strategy to compensate the losses of colored modules, when integrated in an efficient way.

Outlook

The photovoltaic market is driven by the price per watt. The process of power rating is subject to measurement uncertainties and its economic impact is significant to the PV industry. In a scenario where the 27 IEA PVPS countries installed at least 83,4 GW in 2017 [IEA PVPS T1-34], every 1% of uncertainty would cost at least 417M€ per year assuming a nominal price of 0.5€/Wp in silicon modules.

The ENHANCE project was meant to explore new test procedures and measurement uncertainties intended for new modules entering the market by promising either higher energy yields or added value due to aesthetics appearance and consequently to support Swiss leading research institutes and module manufacturers.

An increasing number of coloured modules are reaching the market promising added value due to better building integration and aesthetics. The energy yield of these modules changes significantly by customizing the product (layer position, colour/s, uniformity, transparency and opacity). Compared to standard transparent c-Si modules the spectral mismatch error and angle of incidence effects have a higher impact on the measurement accuracy.